Industry news|2022-02-17| admin

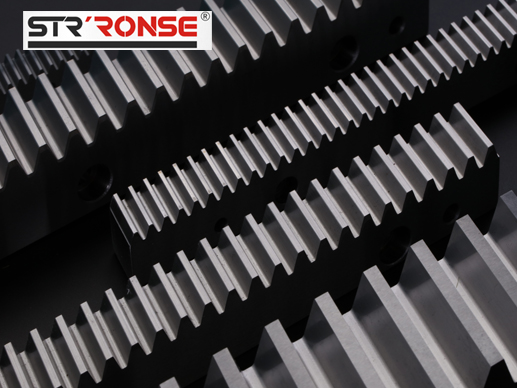

A large number of grinding racks are generally manufactured by mechanical equipment, and the precision of the grinding racks is relatively good. Generally, after the rack is ground, the machining accuracy can be greatly improved. When the rack is ground, there are fine abrasives and abrasives on the surface of the workpiece. These workpieces cooperate with additives to make the rack produce complex relative motion. So what are the processing standards and processes for grinding gear racks? Take a look

For the modular rack, the difficulty is the π value. Generally, the screw pitch of the milling machine is 6mm, and the π value is a decimal, which is difficult to index directly. If it is simplified, it will be easier to operate. ①The indexing is carried out by the indexing hanging wheel; ②The pitch of the screw is changed. When calculating the indexing hanging wheel, the size of the calculated indexing error value depends on the size of the error of the substitution ratio of π. For many calculation of the substitution ratio of π, π≈3.1428571=(22/7), The error value is: 0.0012644.

According to our production practice over the years, for a small amount of grinding and rack processing, our approach is: do not add any indexing mechanism and indexing hanging wheel, completely use the original milling machine accessories, end milling head, indexing head. Its calculation indexing error is less than 0.0000002mm, which is simple, practical, convenient and reliable. One of the processing methods is briefly introduced as follows: the milling machine is X62W, the pitch of the lead screw is 6mm, the fixed number of the indexing head is 40, and the number of holes of the indexing plate is 34 holes. Degree head spindle hanging wheel/screw screw hanging wheel = 1/1), after milling one tooth, shake the indexing handle 20 turns, and then turn the 34-hole circle through 32 hole pitches. If the rack to be processed is a 2-module, then (the indexing head spindle hanging wheel/screw hanging wheel)=(2/1), and the rest are analogous.

For the machining of large-module racks, a finger-shaped rack cutter can be used. For rack processing of small modules, a special single-angle 40° rack milling cutter can be installed on the tool holder, and the end milling head can be turned by 20° (90°-70) for processing. If there is only one rack to be processed, and There is no special single-angle 40° rack milling cutter, and it can also be modified with a three-sided edge milling cutter or saw blade milling cutter of appropriate thickness. The two faces are milled twice. That's it.

Description of 3 grinding methods for racks:

1. Soft abrasive grinding: During the grinding process, the working surface of the grinding tool is coated with chromium oxide as the abrasive for the abrasive. Since the abrasive is softer than the grinding tool and the workpiece, the abrasive is suspended between the workpiece and the grinding tool during the grinding process. Using the chemical action of the abrasive and the surface of the workpiece, a soft oxide film is produced, and the film at the bump is easily ground off by the abrasive.

This method can have relatively fine surface roughness.

2. Wet grinding: During the grinding process, apply abrasive on the grinding tool and grind with dispersed sand. In addition to sand, the abrasives also contain kerosene, engine oil, oleic acid, stearic acid and other substances.

During the grinding process, some sand grains exist between the grinding tool and the workpiece. At this time, the sand grains are mainly used for rolling grinding, with high productivity and high roughness. It is used for general roughing, but the machined surface is generally dull.

3. Dry grinding: a small amount of lubricating additive should be applied to the grinding tool during grinding. The sand is basically fixed on the grinding tool during the grinding process, and its grinding action is mainly sliding grinding.

This method can achieve high tooth surface accuracy and small surface roughness, but the productivity is not high.

The above is about the relevant standards and processes of grinding rack and pinion processing. Shenzhen sz-windrive specializes in the production of rack and pinion. More rack-related knowledge is welcome!